Develivery time:30-45 working days

Model:HAIXING-CU

Payment:30% T/T deposit,70% balance before shipping

Warranty :2 years for machinery warranty

Voltage:Standard 380V 50HZ 3Phase or customized.

Email: elaine@hx-machinery.com

WhatsApp: 008613163076790

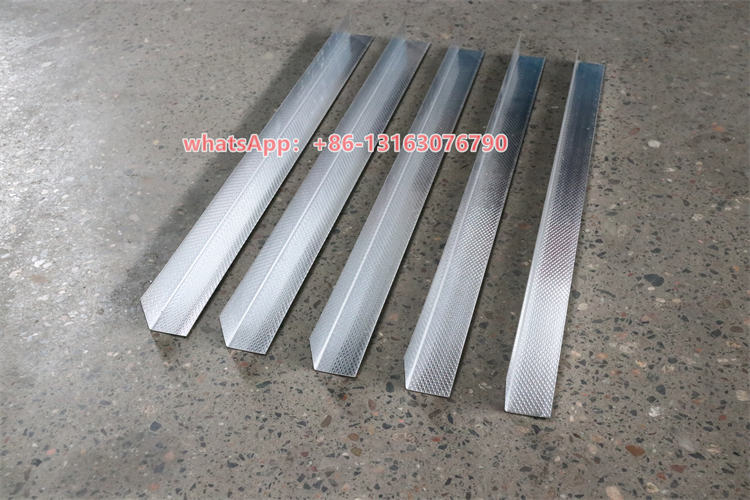

The angle keel forming machine normally size is 24*24 and 30*30mm, one machine can produce different size, it also can customized as customer need size, our angle forming machine has the following advantages:

1.Fast forming speed: The angular keel machine can quickly process steel into the required shape and improve production efficiency.

2.High output: A large number of angular keels can be produced in a short time to meet market demand.

3.No damage to the coating: The coating of the steel will not be damaged during the forming process, ensuring the quality of the product.

4.Various cross-sectional forms: Various cross-sectional forms of angular keels can be produced as needed to adapt to different use conditions.

5.Increasing the yield point of steel: Through plastic deformation during the forming process, the yield point of the steel is increased, and the strength of the product is increased.

| Raw material | GI GL PPGI PPGL |

| Thickness | standard 0.3-1.2 or other thickness as you need |

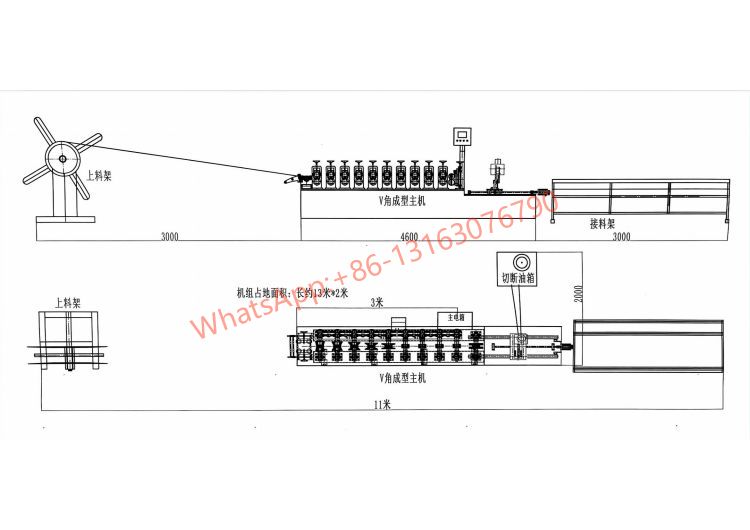

| Machine size | around 5.8*1.1 *1.6m |

| Machine weight | around 3ton |

| Rollers | around 10 rollers, it depends on the profile drawing |

| Roller material | CR12 Steel ,Quenched treatment |

| Maine motor | 5.5kw |

| Pump motot | 5.5kw |

| Shaft diameter | 40mm |

| Maine structure | Arch structure |

| Transmission | Gear/ gear box |

| Control systerm | PLC control |

| Punch hole | it can do , it depend on customer need |

| Press word or logo | it can do ,it depend on customer need |

It include decoiler machine 2.5Ton, roll forming machine, PLC, Touch screen, servo cut, output table 3meters

1.standard export package

2. Plastic film package, and water proof package in 20 ft container

1. 2 years warranty on BL date

2. Upgrading and transformation: Based on technological development and user needs, we provide equipment upgrading and transformation services to improve equipment performance and functions.

3. Customer return visits: Regularly conduct return visits to customers to understand equipment usage and customer satisfaction, so as to continuously improve the quality of after-sales service.

Our machine has been exported to over 128 countries, it include USA, Canada, Mexico, Guayana, Dominican republic, Chile, Peru, Franch, German, England, Geogria, Morocco, Kenya,South Africa...... every customer is not only our customers also our good friend, we supply good quality machine and good service to dear customers to achieve win win.