Develivery time:30-45 working days

Model:HAIXING-CU

Payment:30% T/T deposit,70% balance before shipping

Warranty :2 years for machinery warranty

Voltage:Standard 380V 50HZ 3Phase or customized.

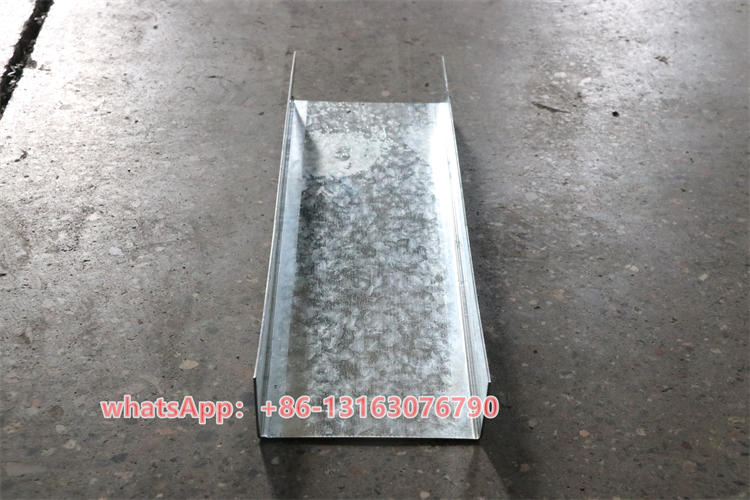

Our metal stud and track roll forming machine is High degree of customization to meet the diverse needs of customers; fast changeover capability to adapt to market changes; advanced control system to ensure production accuracy; easy cleaning and maintenance to save time and energy; low requirements for operators to facilitate personnel arrangement; good compatibility to improve overall efficiency; long service life to achieve long-term benefits, our Metal stud and track roll forming machine has the following significant advantages:

High degree of automation: reduces the possibility of human error and improves the stability and reliability of production.

Saves manpower: no need for a large number of manpower to participate in the changeover operation, reducing labor costs.

Improves competitiveness: The characteristics of high efficiency, precision and strong adaptability help enterprises improve their competitiveness in the market.

| Raw material | GI GL PPGI PPGL |

| Thickness | standard 0.5mm or other thickness also can do up to 1.5mm |

| Machine size | around 6*1.2 *1.6m |

| Machine weight | around 3 ton |

| Rollers | around 12 rollers, it depends on the profile drawing |

| Roller material | CR12 Steel ,Quenched treatment |

| Maine motor | 5.5kw |

| Pump motot | 4kw |

| Shaft diameter | 50mm |

| Maine structure | Arch structure |

| Transmission | Gear/ gear box |

| Control systerm | PLC control |

| Production | 50 meters/minutes |

| Punch hole | it depend on customer need |

| Press word or logo | it depend on customer need |

1.Decoiler machine 2.5Ton-manual decoiler/ hydraulic decoiler

2.metal stud and track roll forming machine body

3.PLC, Touch screen

4.Servo cut

5.Main motor, hydraulic pump motor

6.Output table 3meters-manual output table/ electric out put table

1.machine is nude pack in 20ft container

2.plastic film wrapping package

3.fixed well with steel rope

4.standard export package

1. Multilingual technical support: Provide after-sales technical consultation and guidance services in multiple languages to facilitate communication with customers from different countries.

2. Twenty four month warranty on BL date

3.Localized parts warehouse: Set up localized parts warehouses in some key areas to speed up the delivery of parts.

4.Cooperation with local maintenance services: Establish cooperative relationships with local professional maintenance service agencies to ensure timely door-to-door maintenance services.

5.Regular cross-border return visits: Arrange after-sales personnel to conduct regular cross-border return visits to understand customer usage and needs.