Develivery time:30-45 working days

Model:HAIXING-CU

Payment:30% T/T deposit,70% balance before shipping

Warranty :2 years for machinery warranty

Voltage:Standard 380V 50HZ 3Phase or customized.

In the realm of precision engineering for construction, our Steel stud and track roll forming machinesstands at the forefront of innovation. Crafted with cutting-edge technology and an unwavering commitment to excellence, our machine redefines the production of steel framing components. Whether you are engaged in residential, commercial, or industrial projects, our Steel stud and track roll forming machines offers a fast, accurate, and reliable solution for crafting the resilient structures your projects demand.

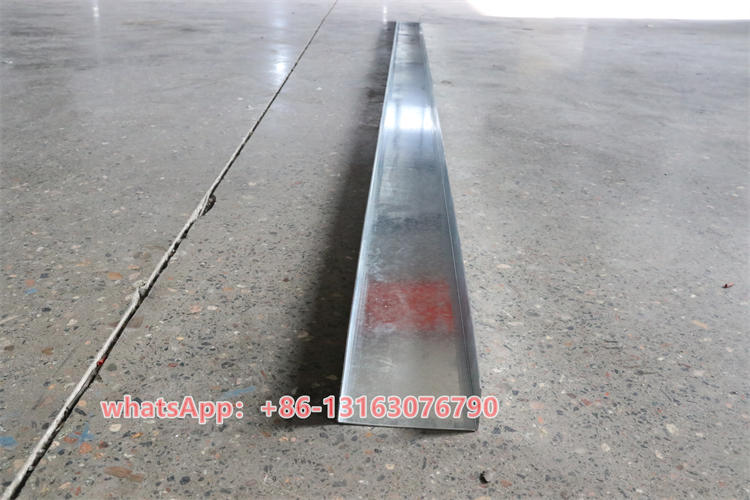

| Raw material | GI GL PPGI PPGL steel coil |

| Thickness | standard 0.5mm or other thickness as customer need |

| Machine size | around 6*1.2 *1.6m |

| Machine weight | around 3 ton |

| Rollers | 12 rollers, it depends on the profile drawing |

| Roller material | CR12 Steel ,Quenched treatment |

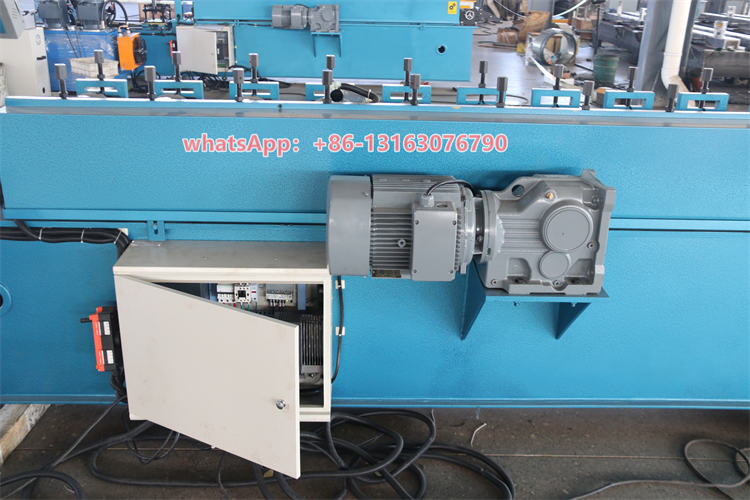

| Maine motor | 5.5kw |

| Pump motot | 4kw |

| Shaft diameter | 50mm |

| Maine structure | Arch structure |

| Transmission | Gear/ gear box |

| Control systerm | PLC control |

| Production | 50 meters/minutes |

| Press word or logo | it depend on customer need |

| Punch hole | it depend on customer need |

1.Decoiler machine 2.5Ton-manual decoiler/ hydraulic decoiler

2.metal stud and track roll forming machine body

3.PLC, Touch screen

4.Servo cut

5.Main motor, hydraulic pump motor

6.Output table 3meters-manual output table/ electric out put table

1.Keel machines play a crucial role in various construction applications, providing efficient solutions for creating structural frameworks. Their applications include:

2.Drywall Systems:Keel machines are extensively used in the construction of drywall systems. They produce metal studs, tracks, and furring channels, forming the skeleton for walls and partitions.

3.Ceiling Systems:In ceiling systems, keel machines manufacture components like ceiling channels and T-bars. These elements contribute to the stability and support of suspended ceilings.

1. 24months aftersales services on BL date.

2. 24 hours online services with professional after-sales service colleague who can speak in Spanish, English, Chinese.

3. We will send you machine manual book and operation work video

4. If you need our engineer come to your factory to debug the machine, you should be responsible for the engineer visa, air ticket, accommodation, and wage