Develivery time:30-45 working days

Model:HAIXING-CU

Payment:30% T/T deposit,70% balance before shipping

Warranty :2 years for machinery warranty

Voltage:Standard 380V 50HZ 3Phase or customized.

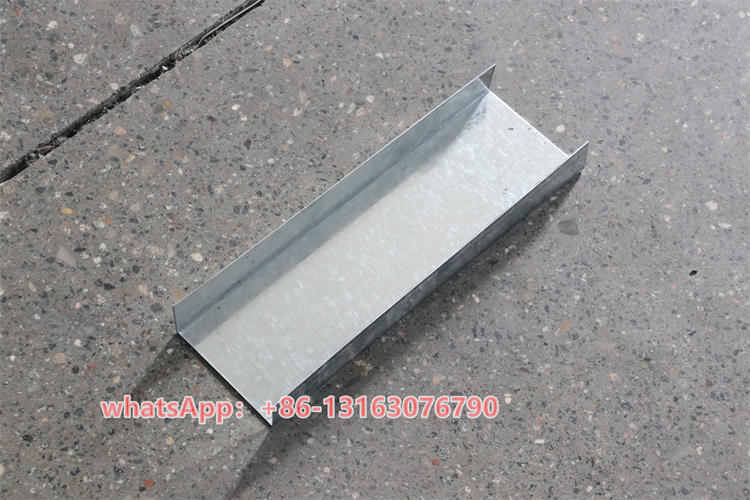

Haixing stud and track machine sold well in domestic and abroad, our stud and track roll forming machine can produce stud and track 40-100mm, thickness 0.5-1.2mm . We adopt arch structure with 30mm and servo cut, the work speed is fast, the standard speed is 50m/min, , our Light steel keel machine has the following significant advantages:

1. Save materials: Reduce material waste and production costs through reasonable design and precise control.

2. Simple operation: It is usually equipped with a simple and easy-to-understand operation interface, and operators can quickly get started after training.

3. Good stability: The operation is stable and reliable, the failure rate is low, and the maintenance and downtime are reduced.

1

| Raw material | GI GL PPGI PPGL |

| Thickness | standard 0.3-0.8 or other thickness also can do up to 1.5mm |

| Machine size | around 5.9*1.2 *1.6m |

| Machine weight | around 3ton |

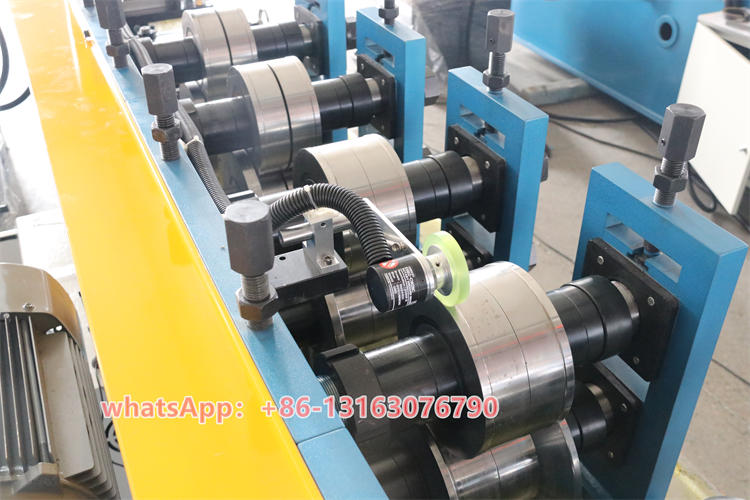

| Rollers | around 14 rollers, it depends on the profile drawing |

| Roller material | CR12 Steel ,Quenched treatment |

| Maine motor | 7.5kw |

| Pump motot | 4kw |

| Shaft diameter | 50mm |

| Maine structure | Arch structure |

| Transmission | Gear/ gear box |

| Control systerm | PLC control |

| Production | 30-60 meters/minutes |

| Punch hole | it depend on customer need |

| Press word or logo | it depend on customer need |

1.Decoiler machine 2.5Ton-manual decoiler/ hydraulic decoiler

2.Stud and track roll forming machine roll forming machine

3.PLC, Touch screen

4.Servo cut/ Stop cut

5.output table 3meters-manual output table/electric out put table

1.Indoor partition renovation: play a role in the renovation of some special spaces.

2.Garden landscape construction: such as the frame structure of some landscape pavilions.

3.Equipment protection fence: create a protective fence structure.

1. 24 month warranty on BL date, in the warranty, the spare parts is free

2. Installation and debugging: Professional technicians will go to the site to install and debug the equipment to ensure that the equipment can operate normally.

3. Training guidance: Provide comprehensive training for operators, including knowledge and skills in equipment operation, maintenance, etc., to help them use the equipment better.