Develivery time:50-60 working days

Model:HAIXING-CU

Payment:30% T/T deposit,70% balance before shipping

Warranty :2 years for machinery warranty

Voltage:Standard 380V 50HZ 3Phase or customized.

Z profile machine is a kind of mechanical equipment specially used for producing Z-shaped purlins, which has a wide range of applications in the construction industry. The following are some of the main application areas of z profile machine:

Steel structure building

Roof structure: Z purlins are often used in the roof system of steel structure buildings as a skeleton to support the roof panel, providing the necessary strength and stability.

Wall support: In the wall panel support system of steel structure buildings, Z purlins are used to fix wall materials, such as color steel plates, glass curtain walls, etc.

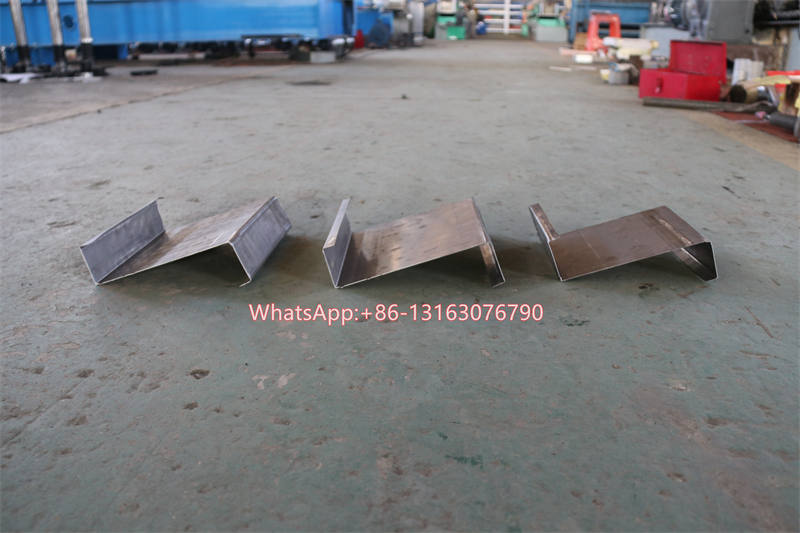

Photo of z profile machine for reference

|

Name

|

z profile machine

|

|

Suitable to process

|

Galvanized steel strips/cold rolled strips

|

|

Roller

|

12Rows

|

|

Dimensions

|

6*1.3*1.5m

|

|

Motor Power

|

5.5kw

|

|

Pump Station Motor

|

5.5Kw.Lichao Brand

|

|

Thickness of the plate

|

1.0mm-3.0mm

|

|

Productivity

|

10-15m/min

|

|

Side wall

|

20mm

|

|

Material of the cutting blade

|

Cr12MoV,Quenched treatment 58ºC-60ºC

|

|

Diameter of the roller

|

80mm

|

|

Weight

|

About 5000Kgs

|

|

Main structure of the machine

|

450 H steel

|

|

Control system

|

PLC control

|

|

Drive mode

|

Motor drive

|

|

Rolling materials

|

GCr15(bearing steel)

|

Energy saving and environmental protection, green production ——

Energy-saving design, reduce energy consumption, reduce production costs. Comply with environmental protection standards and help build a green building system.

Stable and reliable, reduce maintenance costs ——

The equipment has a solid structure and low failure rate, ensuring long-term stable operation. Convenient maintenance design shortens maintenance time and reduces maintenance costs.

After-sales service of z profile machine

24 months after-sale service from BL date

We will send customer a manual in English or Spanish so that you understand all the meanings of the buttons and how to start the machine.

When customers have new process requirements, the after-sales team will make the purlin machine adapt to the new production mode through software upgrades;

When the customer's factory relocates, professional assistance allows the keel machine to quickly resume production in the new environment.

Our customers