Develivery time:30-45 working days

Model:HAIXING-CU

Payment:30% T/T deposit,70% balance before shipping

Warranty :2 years for machinery warranty

Voltage:Standard 380V 50HZ 3Phase or customized.

Email: elaine@hx-machinery.com

WhatsApp: 008613163076790

Application of Hat channel roll forming machine in Construction:

Hat channel , known for their unique shape, find diverse applications in construction, providing essential support and structural integrity in various scenarios.

Suspended Ceilings:Hat channel roll forming machine are commonly used in the installation of suspended ceilings. Their design allows for efficient support of ceiling tiles and other suspended elements.

Light Structural Framing:In light structural framing,Hat channel roll forming machineserve as reliable components for creating sturdy frameworks. They are often employed in residential and commercial construction for their strength and versatility.

Interior Partitions:For constructing interior partitions, Hat channel roll forming machine offer an excellent solution. They provide a robust framework for dividing spaces in both residential and commercial buildings.

| Raw material | Galvanized steel coil |

| Thickness | standard 0.3-0.8 or other thickness also can do up to 1.5mm |

| Machine size | around 5.8*1.1 *1.6m |

| Machine weight | around 3ton |

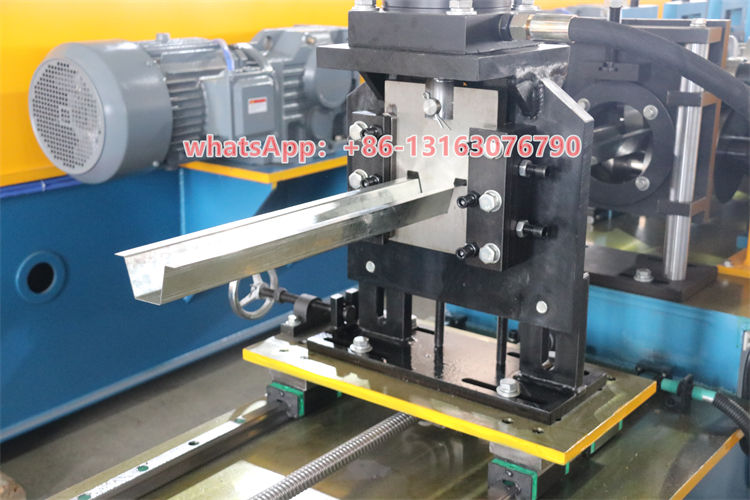

| Rollers | around 12-14 rollers, it depends on the profile drawing |

| Roller material | CR12 Steel , Quenched treatment with high temperature |

| Maine motor | 5.5kw |

| Pump motot | 4kw |

| Shaft diameter | 50mm |

| Maine structure | Arch structure |

| Transmission | Gear/ gear box |

| Control systerm | PLC control |

| Punch hole | it depend on customer need |

| Speed | 50 meters/ minutes |

it include decoiler machine 2.5Ton, roll forming machine, PLC, Touch screen, servo cut, Main motor, pump station motor, output table 3meters

Our Hat channel roll forming machine are meticulously packaged for secure export, ensuring they reach their destination in optimal condition. The packaging process includes:

1.Bare Packing:The Hat channel roll forming machine is wrapped without additional covering to prevent dust or moisture accumulation during transit.

2.Waterproof Covering:A waterproof plastic covering is applied to protect the Hat channel roll forming machinefrom water damage, especially during sea freight.

3.Secure Fixation in a 20-foot Container:

At HAIXING, we pride ourselves on delivering not just a product but an ongoing partnership. Our after-sales service for theHat channel roll forming machine is designed to ensure your satisfaction and operational success.

1.Two-Year Warranty: Your investment is protected by our comprehensive two-year warranty, covering manufacturing defects and providing you with the assurance of a reliable product.

2.24/7 Technical Assistance: Our dedicated team of technical experts is available 24/7 to provide assistance, answer queries, and address any concerns you may have regarding the operation of your Hat channel roll forming machine.

Our Hat channel roll forming machine have been successfully sold to more than 100 countries around the world, mainly the United States, Canada, Mexico, Guayana, Chile, Peru, Dominica, Ecuador, Philippines, Thailand, Vietnam, Saudi Arabia, South Africa, Morocco,Kenya...