Roll forming machine for sale south africa ibr sheet making machine

The ibr sheet roll forming machine is widely used in the roof and wall construction of industrial and civil buildings such as factories, warehouses, gymnasiums, exhibition halls, theaters, etc. in Africa, providing beautiful and durable roof and wall materials for the buildings.

Roll forming machine for sale south Africa , welcome contact us to know more about ibr sheet making machine

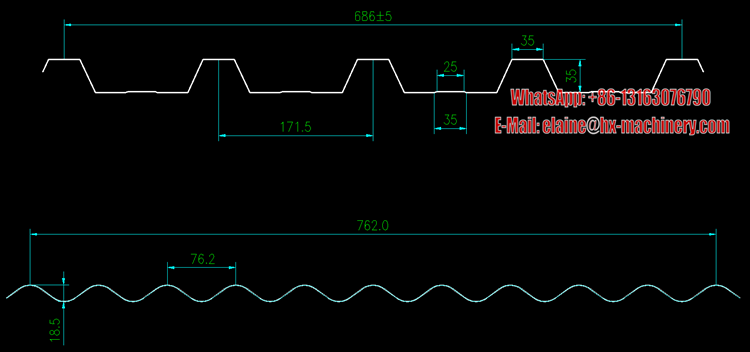

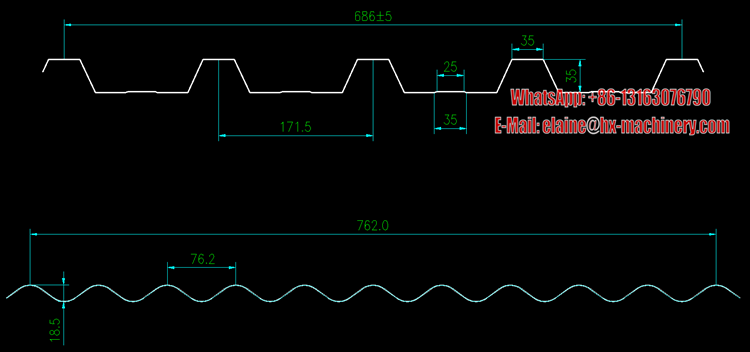

Main parameters of roof sheet making machine south africa price

| Raw material |

Color steel coil, aluminum steel coil, galvanized steel coil |

| Thickness |

standard 0.3-0.8 mm |

| Raw material feeding width |

925mm |

| Machine size |

around 9*1.5 *1.8m |

| Machine weight |

around 5ton |

| Rollers |

around 18 rollers, it depends on the profile drawing |

| Roller material |

number 45 steel |

| Maine motor |

5.5kw |

| Pump motot |

4kw |

| Shaft diameter |

75mm |

| Control systerm |

PLC control, automatic produce |

| Decoiler |

7ton manual decoiler for free. And hydraulic decoiler is your option |

| Out put table |

3meter no power out put table for free. Auto stacker is your option |

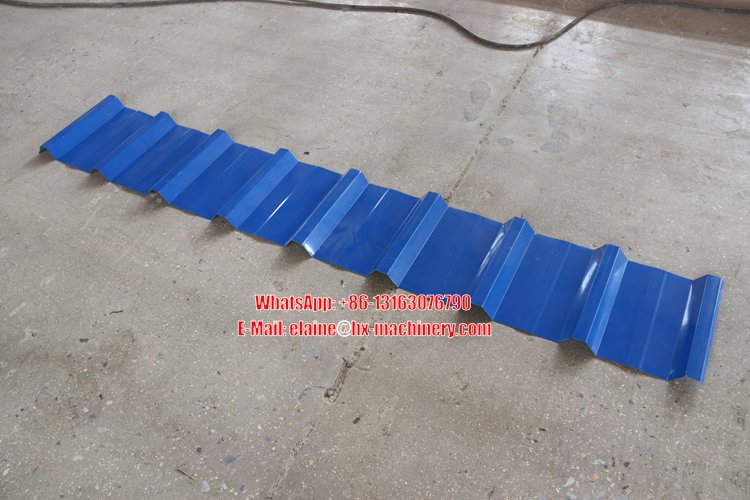

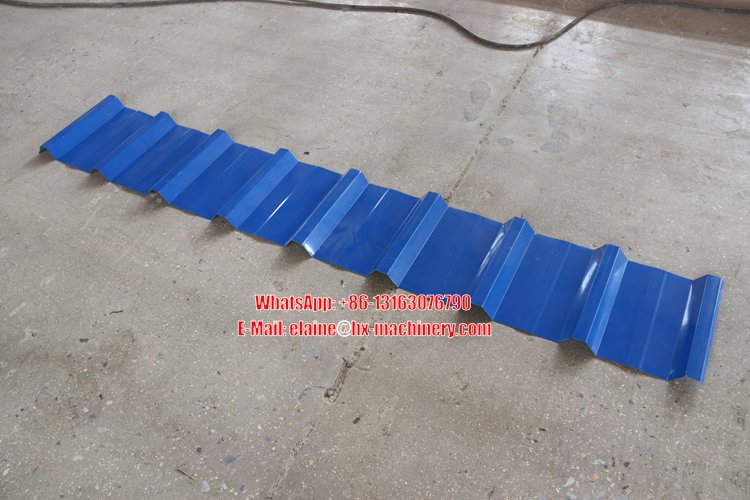

Roof sheet making machine South Africa photo for reference

After sales services and instal of roof sheet making machine south africa price

To begin with, prior to the shipment, we conduct a comprehensive adjustment of the machine in our factory. We will inquire about the specific size you intend to produce and then configure the machine accordingly, fine-tuning all the relevant parameters. This way, upon receiving the machine, you can commence production without the need for any further adjustments.

Secondly, during the disassembly process for debugging purposes, we record detailed videos. These videos are machine-specific and will illustrate the step-by-step procedures for reconnecting the cables and tubes, adding lubricants, and assembling the physical components. This visual guide is designed to assist you in understanding and replicating the setup process with ease.

Finally, once you have received the equipment, we will establish a communication group on either WhatsApp or WeChat. Our engineer, who is proficient in English and Russian, and I, who am fluent in English, Spanish, and French, will be available in the group to address any questions or concerns you may have. Our aim is to provide you with prompt and effective support throughout the installation and initial operation of the machine.