Delivery:30-45 workdays

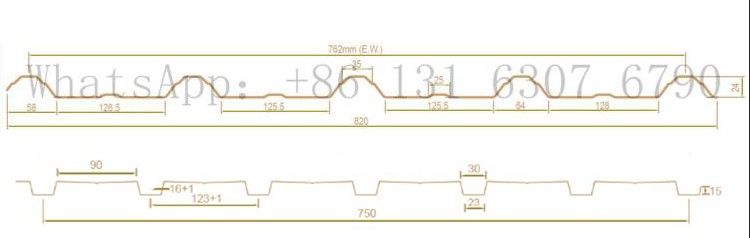

Model:HX-double decker1-S16

Payment: 30% T/T deposit and 70% balance before shipping

Warranty Period:2 years

Operating Voltage: 380v 50hz 3phase(as your require)

wall cladding and steel roofing machine

Tianjin Haixing is a renowned roll forming machine manufacturer with 28+ years of industry experience. Our customers are spread across the globe, including Germany, the USA, Mexico, Peru, Chile, Guatemala, Colombia, Bolivia, Brazil, Kuwait, Indonesia, South Africa, and more. We specialize in meeting the unique requirements of different countries, such as profile customization, language settings, material thickness, user-friendly manuals, installation assistance, and online after-sales support. Our machines feature medium to high-end configurations, incorporating top-brand PLCs and inverters for extended service life, remote operation, multifunctionality, and energy efficiency.wall cladding and steel roofing machine.Tiles of different styles and specifications can be produced, and the double-layer tile pressing machine can meet the diverse needs of different markets and customers.

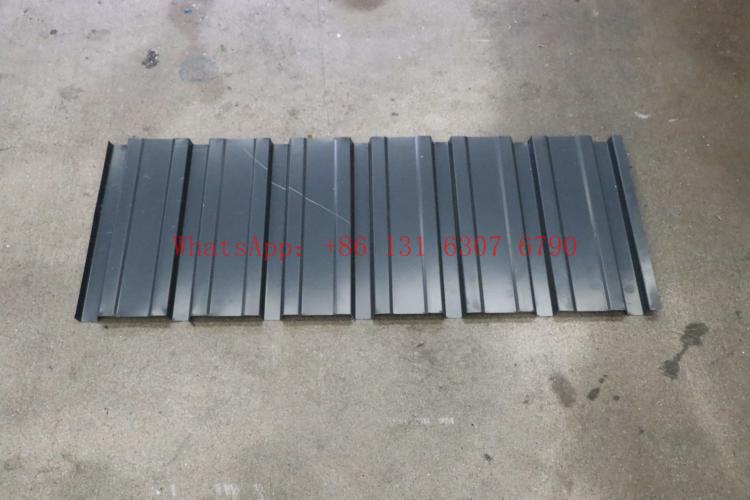

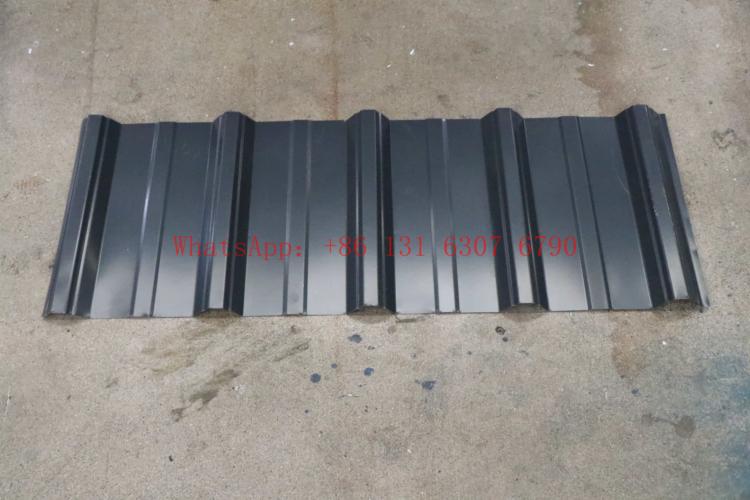

wall cladding and steel roofing machine pictures

wall cladding and steel roofing machine details

| Control system | PLC control |

| Voltage | 380V 50Hz 3phases or as your needs |

| Chain Wheel and Cycle Chain | 1 Inch |

| Processing precision | Within 1.0mm |

| Main structure of the machine | 350H beams |

| Weight | About 5.5ton |

| Diameter of the roller | Φ90mm(depends on different design) |

| Rolling materials | 45# forging steel with chromium plate |

| Roller | 13+13 Rows |

Advantage

1.Precision Cutting:Advanced control mechanisms in our machines ensure that each cut meets exact specifications.

2.High-Quality Raw Materials:The raw materials in our machines are carefully selected to ensure they meet the highest quality standards.

3.Our machines can handle a variety of materials, including galvanized sheets, color steel sheets, and high-strength sheets.

4.Featuring a PLC control system, our machines allow for simple parameter adjustments and one-touch operation.

After-sales service

Equipment operation training:To enhance operational efficiency, we offer detailed training to help your team use the machines correctly.

FAQ

Are you a manufacturer?

Our company has been dedicated to manufacturing cold roll forming machines for nearly three decades, providing trusted solutions worldwide.