Delivery time:25-35 days

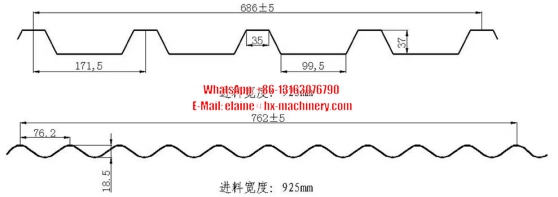

Model: IBR686 and Corrugated 762

Payment:30% T/T deposit,70% balance before shipping

Voltage:380V 50HZ 3Phase or based on customer’s need.

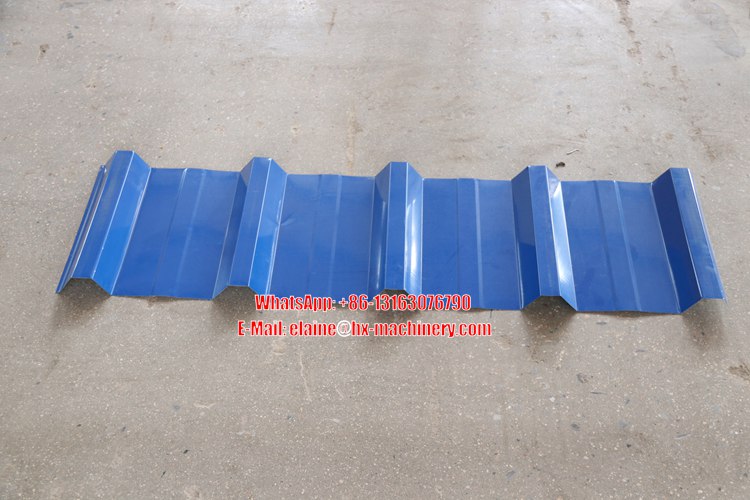

Double layer roof machine: Not only can it produce standard IBR board types, but it is also compatible with the production of other similar board types, for example corrugated roof sheet, or tile roof sheet, providing users with more choices to adapt to different architectural styles and design requirements. For example, in European-style buildings and modern minimalist buildings, the board type can be flexibly switched according to the design.

| Raw material | Color steel coil, aluminum steel coil, galvanized steel coil |

| Thickness | standard 0.3-0.8 mm |

| Raw material feeding width | 925mm |

| Machine size | around 9*1.5 *1.8m |

| Machine weight | around 5ton |

| Rollers | around 18 rollers, it depends on the profile drawing |

| Roller material | number 45 steel |

| Maine motor | 5.5kw |

| Pump motot | 4kw |

| Shaft diameter | 70mm |

| Maine structure | Middle plate 16mm |

| Transmission | Chain drive |

| Control systerm | PLC control, automatic produce |

It include decoiler machine 7Ton, roll forming machine, PLC control systerm, Touch screen, Hydraulic cut, electric control system, output table 3meters

For the double layer ibr making machine price in south africa, they will be provided with nude packing as the standard option and pack them with waterproof plastic to safeguard the equipment during transportation and storage.