Delivery time:25-35 days

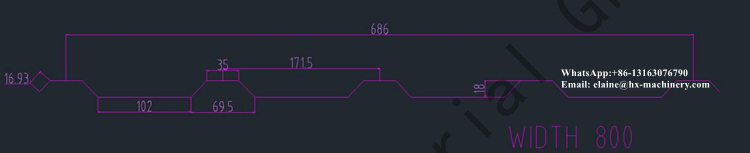

Model: IBR686

Payment:30% T/T deposit,70% balance before shipping

Voltage:380V 50HZ 3Phase or based on customer’s need.

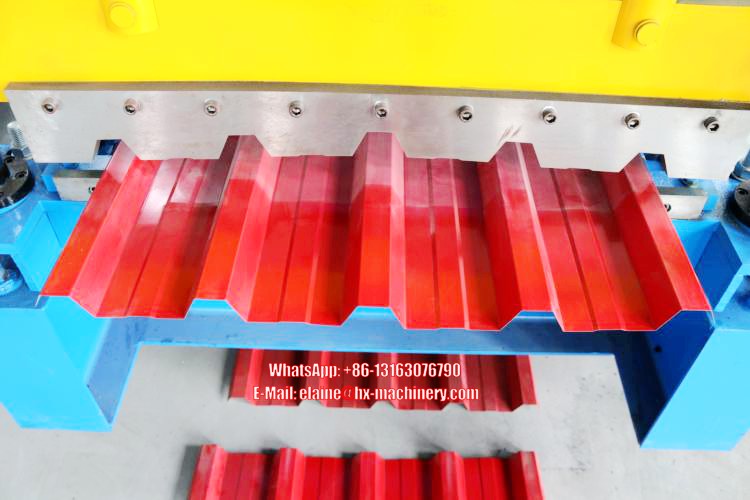

HAIXING Machine Applications:

Our IBR roof sheeting machines are extensively used in the manufacturing of roofing materials for a wide range of structures, including residential homes, factories, warehouses, office buildings, and more.

Energy-Efficient and Environmentally Friendly:

Designed with sustainability in mind, our machines consume minimal energy, operate with low noise levels, and produce very little dust—ensuring compliance with national environmental protection standards. ibr roll forming machine for sale roof sheet rollformer, please feel free to contact Haixing company

User-Friendly Operation:

The equipment features an ergonomic design with an intuitive control interface, making it easy to operate and accessible for users of all experience levels

| Raw material | Color steel coil, aluminum steel coil, galvanized steel coil |

| Thickness | standard 0.3-0.8 mm for roof ibr sheet roll forming machine |

| Raw material feeding width | 925mm |

| Machine size | around 9*1.5 *1.8m |

| Machine weight | around 5ton |

| Rollers | around 18 rollers, it depends on the profile drawing |

| Roller material | number 45 steel |

| Maine motor | 5.5kw |

| Transmission | Chain drive |

| Control systerm | PLC control, automatic produce |

It include decoiler machine 7Ton, roll forming machine, PLC control systerm, Touch screen, Hydraulic cut, electric control system, output table 3meters

Two-Year Warranty:

Enjoy peace of mind with our comprehensive two-year warranty, which protects your keel machine against manufacturing defects and ensures reliable performance.

Remote Support:

Leveraging advanced technology, we offer remote support services to quickly diagnose and resolve technical issues—reducing downtime and keeping your operations running smoothly.