Delivery time:25-35 days

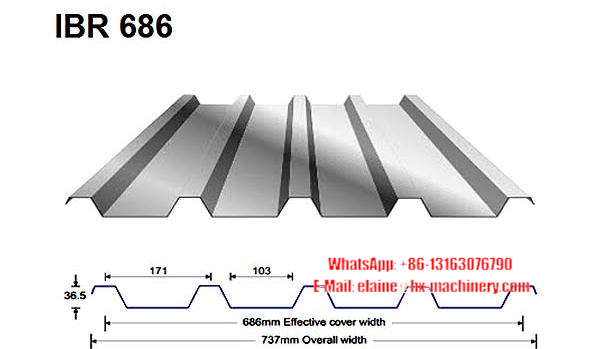

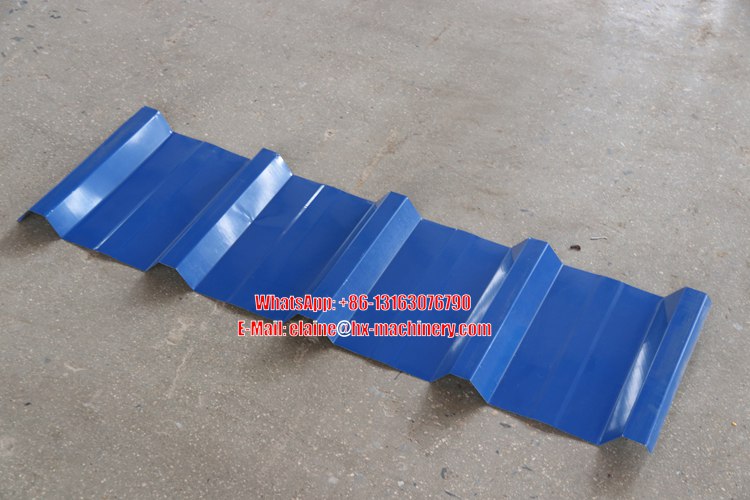

Model: IBR686 and Corrugated 762

Payment:30% T/T deposit,70% balance before shipping

Voltage:380V 50HZ 3Phase or based on customer’s need.

The machine has high production precision: the ibr roof machine ibr roof sheeting roll forming machine can ensure the dimensional accuracy of the tiles to a very high level with extremely small errors through precise molds and advanced control systems, making the splicing between tiles tighter and more beautiful, and improving the overall quality and waterproof performance of the roof or wall.

| Raw material | Color steel coil, aluminum steel coil, galvanized steel coil |

| Thickness | standard 0.3-0.8 mm |

| Raw material feeding width | 925mm |

| Machine size | around 9*1.5 *1.8m |

| Machine weight | around 5ton |

| Rollers | around 18 rollers, it depends on the profile drawing |

| Roller material | number 45 steel |

| Maine motor | 5.5kw |

| Pump motot | 4kw |

| Shaft diameter | 75mm |

| Maine structure | Middle plate |

| Transmission | Chain drive |

| Control systerm | PLC control, automatic produce |

| Decoiler | 7ton manual decoiler for free. And hydraulic decoiler is your option |

| Out put table | 3meter no power out put table for free. Auto stacker is your option |

It include decoiler machine 7Ton, roll forming machine, PLC, Touch screen, servo cut, electric control system, output table 3meters