Develivery time:50-60 working days

Model:HAIXING-CU

Payment:30% T/T deposit,70% balance before shipping

Warranty :2 years for machinery warranty

Voltage:Standard 380V 50HZ 3Phase or customized.

C channel roll forming is flexible and diverse to meet personalized needs -Purlins of various specifications and models can be produced to meet the needs of different building structures. Easy-to-adjust molds can achieve rapid changeovers to meet personalized customization.

Energy-saving and environmentally friendly, green production - Energy-saving design reduces energy consumption and production costs. Comply with environmental protection standards to help build a green building system

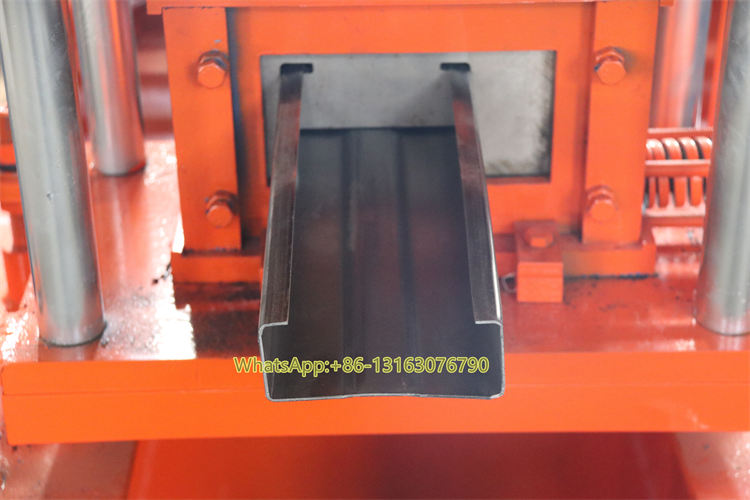

Photo of c channel rolling machine for reference

|

Name

|

c channel roll forming

|

|

Suitable to process

|

Galvanized steel strips/cold rolled strips

|

|

Roller

|

12Rows

|

|

Dimensions

|

6*1.3*1.5m

|

|

Motor Power

|

5.5kw

|

|

Pump Station Motor

|

5.5Kw.Lichao Brand

|

|

Thickness of the plate

|

1.0mm-3.0mm

|

|

Productivity

|

10-15m/min

|

|

Side wall

|

20mm

|

|

Material of the cutting blade

|

Cr12MoV,Quenched treatment 58ºC-60ºC

|

|

Diameter of the roller

|

80mm

|

|

Weight

|

About 5000Kgs

|

|

Main structure of the machine

|

450 H steel

|

|

Control system

|

PLC control

|

|

Drive mode

|

Motor drive

|

|

Rolling materials

|

GCr15(bearing steel)

|

Bare Packing:The machine is wrapped without additional covering to prevent dust or moisture accumulation during transit.

Waterproof Covering:A waterproof plastic covering is applied to protect the machine from water damage, especially during sea freight.

Packed in 20ft container

After-sales service of c channel rolling machine

24 months after-sale service from BL date

Software upgrade service: With the development of technology, the software of the equipment control system is updated and upgraded to improve the performance and function of the equipment.

Accessory customization service: According to the special needs of customers, non-standard accessories are customized to meet the use in specific scenarios

Our customers