Develivery time:30-45 working days

Model:HAIXING-CU

Payment:30% T/T deposit,70% balance before shipping

Warranty :2 years for machinery warranty

Voltage:Standard 380V 50HZ 3Phase or customized.

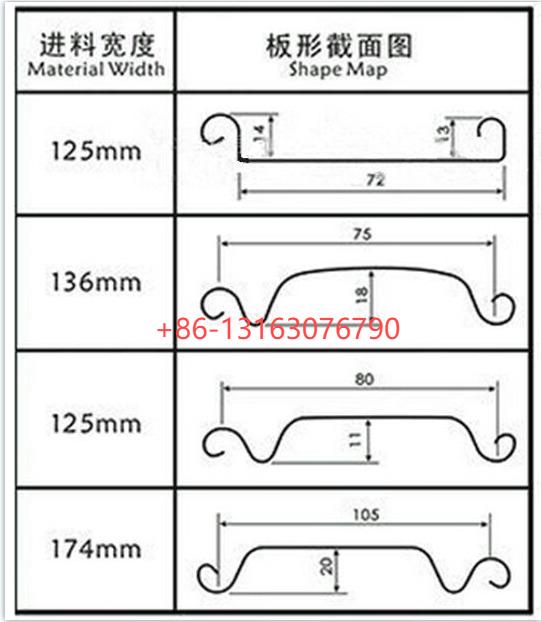

HAIXING shutter door roll forming machine Mainly composed of unloading machine, feeding platform, roll forming, cut device, hydraulic station, computer control system, etc. Applied to the production of rolling shutter doors in various industrial plants, warehouses, supermarkets and shopping malls.

The shutter roll forming machine, through the arch structure, precise chain drive system and automatic control, can efficiently and accurately produce rolling shutter doors of various specifications and types to meet the needs of different occasions.

| Raw material | GI GL PPGI PPGL |

| Thickness | standard 0.4-1 or other thickness as you need |

| Machine size | around 5.8*0.7 *1.5m |

| Machine weight | around 3ton |

| Rollers | around 14 rollers, it depends on the profile drawing, CR12 Steel |

| Cut | Hydraulic cut |

| Maine motor | 4kw |

| Pump motot | 4kw |

| Shaft diameter | 70mm |

|

Structure |

Arch structure |

| Transmission | Chain |

| Control systerm | PLC control |

| Speed | 15m/min |

| Out put table | 3 meter, manual / Pneumatic to choose |

It include decoiler machine 3Ton, feeding, roll forming machine, PLC control, Touch screen, Hydraulic cut, output table 3 meters.

shutter roll forming machine are available with a 2-year warranty and lifetime technical support. In addition, 24-hour online support and on-site installation, commissioning and training services are also provided.

Our customers