Develivery time:50-60 working days

Model:HAIXING-CU

Payment:30% T/T deposit,70% balance before shipping

Warranty :2 years for machinery warranty

Voltage:Standard 380V 50HZ 3Phase or customized.

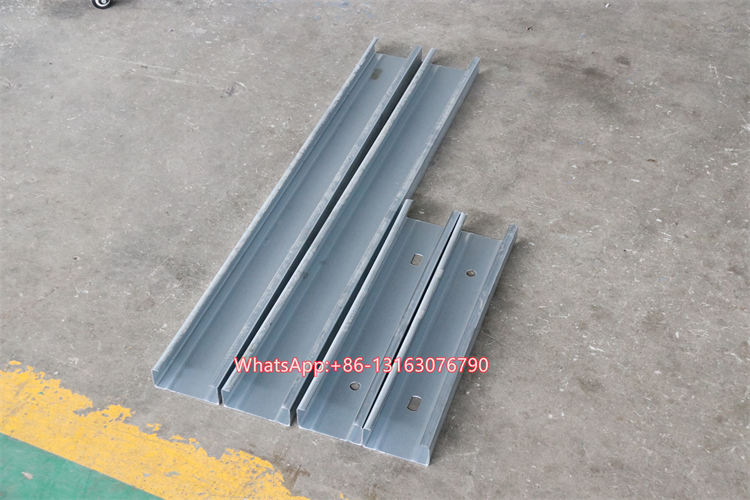

HAIXING fully automatic purlin roll forming machine is an efficient and flexible mechanical equipment, mainly used for the production of C-shaped steel and CZ-shaped steel, with the characteristics of automatic control, precise positioning, and flexible steering.

The main features of the fully automatic purlin machine include:

Automatic control: Through the intelligent management system, the production process is automatically controlled to ensure product quality.

Precise positioning: With high-precision positioning function, the size and shape of the product meet the requirements.

Flexible steering: The equipment has the ability to flexibly turn to adapt to different production needs.

Photo of purlin roll forming machine for reference

|

Name

|

purlin roll forming machine

|

|

Suitable to process

|

Galvanized steel strips/cold rolled strips

|

|

Roller

|

16-18Rows

|

|

Dimensions

|

11*1.3*1.5m

|

|

Motor Power

|

11Kw*2

|

|

Pump Station Motor

|

7.5Kw.Lichao Brand

|

|

Thickness of the plate

|

1.0mm-3.0mm

|

|

Productivity

|

10-15m/min

|

|

Material of the cutting blade

|

Cr12MoV,Quenched treatment 58ºC-60ºC

|

|

Diameter of the roller

|

85mm

|

|

Weight

|

About 8500Kgs

|

|

Main structure of the machine

|

450 H Beams and arch structure

|

|

Voltage

|

380V 50Hz 3phases or as customer’s need

|

|

Control system

|

PLC control

|

|

Drive mode

|

Motor driver

|

|

Rolling materials

|

GCr15(bearing steel)hard chrome plated after heat treatment

|

|

Length Tolerance

|

±2mm

|

|

Type of cutting

|

Length-set cutting Guiding pipe Hydraulic cutter Each side one Oil cylinder |

Standard export package with plastic film package, load in to 40ft container, reinforcement in with rope in the container.

1.24 month warranty, free replacement of accessories during the warranty period

2.Maintenance service: When equipment fails, respond promptly and arrange maintenance personnel to perform maintenance and restore the normal operation of the equipment as soon as possible. Repairs may include replacing parts, fixing faults, etc.

3.Regular maintenance: Provide regular maintenance services, conduct comprehensive inspection, cleaning, lubrication and other maintenance work on the equipment to extend the service life of the equipment.